TTR300 Series Self-Leveling Load-Bearing Epoxy Floor

TTR300 Series Self-Leveling Load-Bearing Epoxy Floor

The TTR300 series is a type of seamless special epoxy floor with a self-leveling surface and different processes and materials used in the bottom and middle layers, which has high wear resistance. It is mainly a decorative floor made on-site with substances such as epoxy resin and quartz sand. It is mainly used for the decoration of the floors of industrial plants and parking lots, such as the plants in industries like electronics, electrical appliances, precision instruments, textile and clothing, printing, packaging, food, and medicine. It is mainly used in occasions with high traffic flow, high wear resistance, impact and heavy load that bear the rolling of forklifts, etc.

Product Features

- Good adhesion to various substrates. Wear-resistant, resistant to heavy pressure and impact.

- Resistant to water, detergents and general chemicals.

- Smooth and seamless finish, beautiful, anti-corrosion and anti-mildew, and easy to clean.

- Compared with the TTR100 variety, the service life is relatively longer, generally more than five years.

Recommended Construction Process

Please refer to the construction guide for details

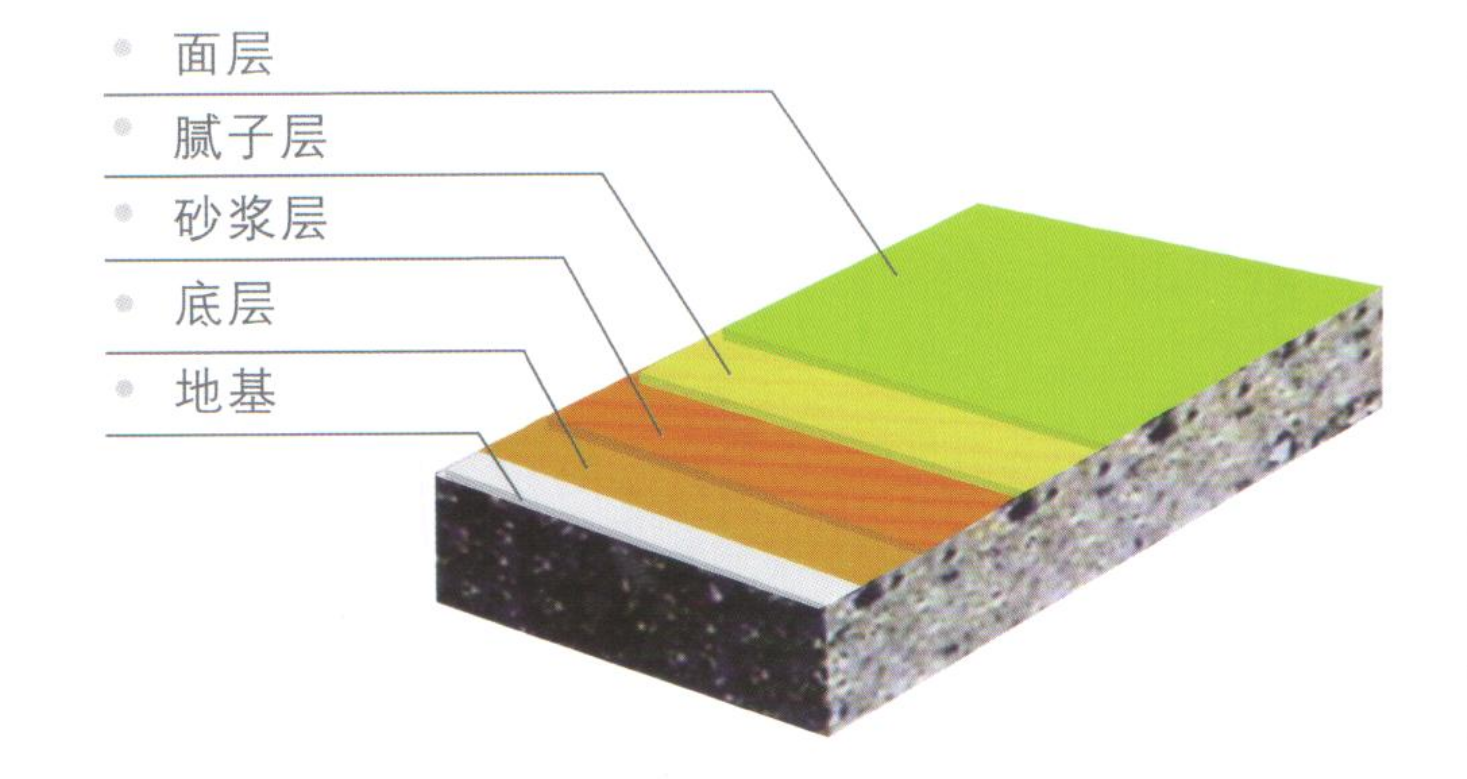

Structural Schematic Diagram

Typical Physicochemical Properties

| Property | Value | |

|---|---|---|

| Drying time, hours | Surface dry | Less than 8 |

| Hard dry | Less than 20 | |

| Washability resistance, times | Greater than 10000 | |

| Hardness, Shore D | Greater than 75 | |

| Wear resistance, 750g/500r, weight loss | Less than or equal to 0.03g | |

| Bonding strength, N/mm² | Greater than 5 | |

| Compressive strength, N/mm² | Greater than 80 | |

| Bending strength, N/mm² | Greater than 8 | |

| Tensile strength, N/mm² | Greater than 8 | |

| Water resistance, soaked in tap water for 30 days | No change | |

| Salt water resistance, soaked in 10% NaCl for 30 days | No change | |

| Alkali resistance, soaked in 20% NaOH for 30 days | No change | |

| Resistance to lubricating oil, soaked in lubricating oil for 30 days | No change |