TTR200 Series Anti-Static Floor

TTR200 Series Anti-Static Floor

The TTR200 series is a type of special floor that can reduce the generation and accumulation of static charges. It can be formulated in any color as required by customers. It is mainly used for anti-static decoration of floors, countertops and walls in industries that are sensitive to static charges, such as electronics, computers, electrical appliances, precision instruments, textile and clothing, printing, packaging, as well as industries involving the processing and transportation of petroleum, organic solvents and powders.

Product Features

- Can endow non-conductors with a bright and colorful anti-static surface decoration.

- Good adhesion to various substrates and wear resistance.

- Resistant to water, detergents and general chemicals.

- Smooth and seamless, beautiful, anti-corrosion and anti-mildew, and easy to clean.

- There are two types: thin coating type and self-leveling type.

Recommended Construction Process

- Base surface treatment.

- Primer coating (used when the base surface is loose)

- Laying conductive power grids.

- Scraping anti-static mortar layer.

- Scraping anti-static intermediate paint.

- Anti-static color paint coating.

Please refer to the construction guide for details.

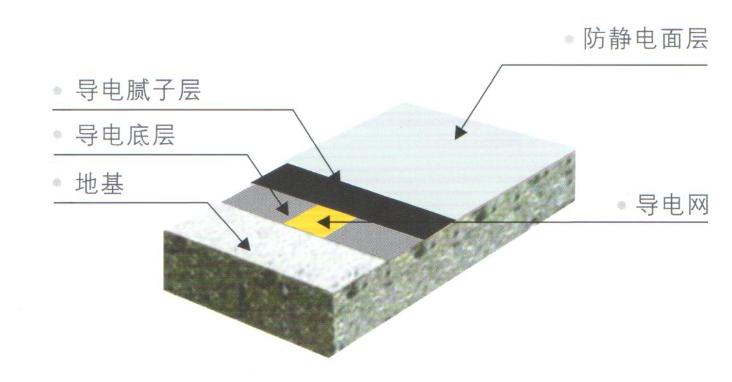

Legend

Typical Physicochemical Properties

| Property | Value | |

|---|---|---|

| Drying time, hours | Surface dry | Less than 5 |

| Hard dry | Less than 20 | |

| Adhesion, grade | 1 | |

| Washability resistance, times | Greater than 10000 | |

| Hardness, Shore D | Greater than or equal to 70 | |

| Impact resistance, kgf.cm | 50 | |

| Flexibility | 3mm | |

| Wear resistance, 750g/500r weight loss | Less than or equal to 0.03g | |

| Water resistance, soaked in tap water for 30 days | No change | |

| Salt water resistance, soaked in 10% NaCl for 30 days | No change | |

| Alkali resistance, soaked in 10% NaOH for 30 days | No change | |

| Surface resistance, Ω | 1x 10<sup>5</sup> - 10<sup>9</sup> |